Developing AI models tailored to the specific machinery and operational patterns of your manufacturing environment. Receive a system capable of predicting equipment failures and scheduling maintenance proactively, reducing downtime and extending the lifespan of machinery.

AI Solutions for Manufacturing Development

AI Solutions for Manufacturing We Provide

Devox can produce different AI applications in manufacturing. From operational solutions to those working alongside your people, we cover a wide spectrum of what artificial intelligence can offer.

-

Predictive Maintenance Development Services

-

Quality Control AI Services

Benefit from real-time detection of defects or inconsistencies, ensuring products meet high-quality standards directly from the machine: Devox creates AI-powered vision systems designed to inspect and ensure product quality at various stages of the manufacturing process.

-

Supply Chain Optimization Services

Let Devox design algorithms that analyze vast amounts of data to predict demand, optimize inventory, and enhance logistics. You will gain a streamlined supply chain with reduced costs, improved efficiency, and timely product delivery.

-

Manufacturing Process Optimization Services

Leveraging AI, we can simulate and analyze your manufacturing processes, identifying its opportunities for efficiency gains based on your existing process. We will provide recommendations for process adjustments that minimize waste, reduce energy consumption, and increase production speed.

-

Robotics and Automation Services

Increase productivity in your manufacturing operations, giving them due flexibility modern developments enable. We’re integrating AI and robotics in manufacturing, providing you with automated solutions for tasks that require high precision, endurance, or speed.

-

Energy Management Services

We’re creating AI systems that monitor and analyze energy usage within manufacturing facilities to identify savings opportunities. You can expect optimized energy consumption, killing two birds of sustainability goals and reduced operational costs with one stone.

-

Worker Safety Monitoring Services

Ensure adherence to safety protocols and detect potential hazards in the manufacturing environment: we’re developing AI-driven monitoring systems that enhance worker safety, reducing the risk of accidents and ensuring compliance with regulations.

-

Customization and Design Services

Cater to individual customer preferences at scale, increasing market competitiveness: we will develop adaptive AI that offers mass customization capabilities, allowing for the rapid design and production of personalized products.

-

Digital Twins Development Services

Designing virtual replicas of physical manufacturing systems, enabling simulation and optimization of processes before implementation. Receive insights into performance improvements and make informed decisions without the risk of physical trials and get a better picture of an end item look.

-

Cognitive Procurement Services

Levergae more agile response to market changes or supply chain disruptions: we make AI systems that to optimize procurement by analyzing supplier data, material costs, and market trends. You’ll achieve improved procurement strategies, cost savings, and enhanced supplier relationships.

-

NLP for Documentation Services

Harness the potential of natural language processing to automate the processing and analysis of textual documents within the manufacturing context. Devox can make a solution that streamlines document management, improves compliance, and saves time on manual documentation processes.

Benefits of AI Solutions for Manufacturing

There’s a wide range of improvements AI in manufacturing industry can provide. See what can be elevated to the next level with custom Devox software.

-

Reach Consistent Quality Control

Enjoy a more accurate, consistent, and faster way to detect defects, in contrast to manual inspections, which are prone to errors. AI-powered visual inspection systems spot quality issues with greater accuracy and speed, ensuring products meet high-quality standards consistently and there are no QA gaps.

-

Stop Energy Waste

Cut back on excessive energy consumption without sacrificing practical results. Let AI in manufacturing sector optimize energy use by identifying inefficiencies and suggesting adjustments, promoting sustainability, and reducing expenses. The Devox-made system will monitor and analyze energy usage patterns in a way to reduce your operational costs, as well as the carbon footprint.

-

Create a Safe Workplace

Identify potential hazards, helping to prevent accidents and ensuring a safer work environment. AI can monitor workplace conditions in real-time, predict potential safety incidents, and ensure compliance with safety protocols by integrating advanced monitoring and predictive analytics to foresee and mitigate hazards. You can also anticipate equipment failures that might pose safety risks, allowing for preventative maintenance.

-

Unlock Customization and Design Flexibility

Tap into yet undiscovered mass customization and meet individual client preferences without sacrificing effectiveness or significantly increasing costs: AI can process and analyze vast amounts of customer data, identifying trends and preferences that inform product design. In production, you’ll optimize processes for custom orders, adjusting parameters in real-time to accommodate different materials, designs, or specifications.

-

Quicken Innovation Cycles

Speed up the innovation process while also significantly cutting down on material and labor costs: AI algorithms analyze design options, predict performance under various conditions, and provide optimization recommendations, enabling quicker iteration and refinement. You’ll streamline the design, prototyping, and testing phases. In terms of R&D processes, AI's capability to simulate and model design concepts in virtual environments reduces the need for physical prototypes.

-

Avoid Skill Gaps and Labor Shortages

Automate routine and complex tasks, mitigating the impact of labor shortages and skill gaps. You’ll allocate human resources to more strategic and high-value activities while not missing out on the lack or exclusivity of high skill in manufacturing: AI-driven robots and machines can learn and adapt to new tasks, augment human capabilities, or even help upskill existing employees, making it easier for you to bridge skill gaps internally.

Key Features of AI Solutions for Manufacturing

Predictive Analytics

AI solutions can analyze historical data and identify patterns to forecast future outcomes, such as equipment failures, demand spikes, or supply chain disruptions, allowing for proactive decision-making.

Machine Learning and Deep Learning

AI and machine learning in manufacturing enable the systems to learn and improve from experience without being explicitly programmed. They are used for a variety of tasks, including predictive maintenance, quality inspection, and process optimization.

Computer Vision

AI-powered computer vision systems can interpret and make decisions based on visual data. In manufacturing, this is often used for quality control, safety monitoring, and guiding robotic systems.

Natural Language Processing (NLP)

This allows AI solutions to understand and generate human language, facilitating the automation of customer service, report generation, and the analysis of unstructured data, such as maintenance logs and product reviews.

Robotics and Automation

AI enhances robotic systems, enabling them to perform complex tasks with high precision and flexibility. This includes assembly, picking and packing, and even tasks requiring fine motor skills or adaptation to changing environments.

Digital Twins

The creation of virtual replicas of physical systems or processes allows for simulation, analysis, and optimization. Digital twins can predict the outcomes of changes in the manufacturing process, reducing the need for physical prototypes and trials.

Data Integration and Analysis

AI solutions can integrate and analyze data from diverse sources, including IoT devices, ERP systems, and external databases. This comprehensive view supports more informed decision-making across all areas of manufacturing.

Real-time Monitoring and Control

AI systems provide real-time insights into manufacturing operations, allowing for immediate adjustments to improve efficiency and productivity. This is critical for optimizing production lines and energy use.

Customization and Personalization

AI enables mass customization by efficiently handling variations in product design and production processes. This allows manufacturers to meet individual customer preferences without sacrificing efficiency.

Collaborative Robots (Cobots)

These robots work alongside human workers, enhancing safety and efficiency. AI enables cobots to learn and adapt to new tasks quickly, making them more versatile and valuable in a manufacturing setting.

Industry Contribution Awards & Certifications

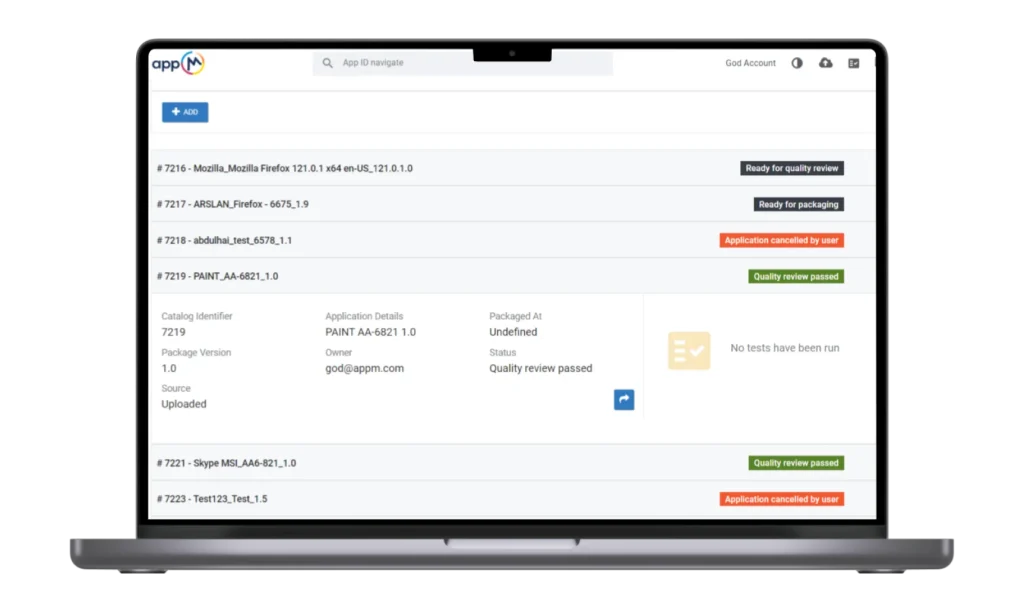

Juriba: Enterprise Digital Workplace Management Platform for Migration & Automation

An enterprise-grade automation platform that streamlines IT project workflows through smart dashboards.

Additional Info

- .NET 6

- MS SQL

- Redis

- Angular

- NgRx

- RxJS

- Kubernetes

- Elasticsearch

United Kingdom

Trusted by

Testimonials

FAQ

-

How long does AI development for manufacturing take?

The development timeline for AI in manufacturing process varies widely based on the complexity of the application and the specific area of focus.

Predictive maintenance solutions might take 3-6 months to implement, leveraging existing models and focusing on machine data analysis.

Quality control systems, particularly those involving computer vision for defect detection, can range from 4-8 months, depending on product diversity and defect complexity.

Supply chain optimization projects, due to their need to integrate vast datasets and multiple systems, could extend from 6-12 months.

Similarly, developing AI for product customization and integration with robotic systems can also take anywhere from 6 months to over a year, reflecting the intricacies of tailoring products to customer specifications and automating complex manufacturing tasks.

These timelines are flexible, influenced by factors such as data availability, technological infrastructure, and the degree of integration required with existing processes.

-

What’s the future of AI in manufacturing?

The future of AI in manufacturing is poised for significant growth and innovation, with smarter, more autonomous systems integrating deeply into production processes. AI will drive further advancements in predictive maintenance, quality control, and supply chain optimization, making manufacturing more efficient, flexible, and responsive to market demands. The rise of AI-powered robotics and cobots will enhance human-robot collaboration, increasing productivity while ensuring safety. Customization will reach new heights as AI enables mass personalization with minimal impact on production efficiency.

Additionally, AI’s role in sustainable manufacturing will become increasingly important, optimizing energy use and reducing waste. As AI technologies evolve, they will continue to transform the manufacturing landscape, ushering in an era of unprecedented efficiency and innovation.

-

How does AI improve predictive maintenance in manufacturing processes?

AI enhances predictive maintenance by continuously analyzing data from sensors and machinery to identify patterns indicative of potential failures. This allows for maintenance to be scheduled at the optimal time, minimizing unexpected downtime and extending the lifespan of equipment. For instance, by monitoring vibration, temperature, and power consumption data, AI algorithms can predict bearing failures in motors before they occur, allowing for planned interventions that prevent costly production halts and maintain high operational efficiency.

-

Can AI solutions enhance safety protocols in manufacturing environments?

Yes, AI significantly boosts safety protocols by employing computer vision and real-time monitoring to detect unsafe behaviors, equipment malfunctions, or hazardous conditions that could lead to accidents. For example, AI-powered systems can monitor video feeds to ensure that workers are wearing the necessary personal protective equipment (PPE) and adhering to safety zones around heavy machinery. These systems can instantly alert supervisors to any deviations, fostering a safer workplace and reducing the risk of injury.

-

How do AI systems adapt to working with various materials in the manufacturing process?

AI systems are trained on vast datasets that include a wide range of materials with different properties, enabling them to understand and predict how these materials react under various conditions. For welding processes, for example, AI algorithms can adjust parameters such as speed, temperature, and material feed rate in real-time to accommodate different metals or alloys, ensuring optimal weld quality. This adaptability not only improves product quality but also reduces waste and increases efficiency.

-

What role does AI play in optimizing supply chains for manufacturers?

AI revolutionizes supply chain optimization by providing predictive insights that improve inventory management, demand forecasting, and logistic efficiencies. For instance, AI algorithms can analyze historical sales data, market trends, and external factors like weather or economic indicators to accurately forecast demand. This allows manufacturers to adjust their production schedules and inventory levels accordingly, reducing overproduction, minimizing stockouts, and ensuring timely delivery to customers.

-

How does AI enhance operations in steel, textile, and automotive manufacturing?

AI In steel manufacturing optimizes operational parameters such as temperature and pressure in furnaces to improve efficiency and yield while employing predictive maintenance to reduce downtime and maintenance costs. It also uses AI-powered vision systems for real-time inspection of steel quality, ensuring only the highest quality products reach the market.

AI in textile manufacturing revolutionizes fabric inspection by automating defect detection, leading to significant improvements in quality and efficiency. It enhances demand forecasting and inventory management, allowing manufacturers to adjust production schedules accurately and manage stock levels effectively, reducing waste and increasing responsiveness to market demands. AI also optimizes the supply chain and enables the production of customized designs by analyzing customer preferences and trends.

AI in car manufacturing is about autonomous robots increasing the efficiency and flexibility of assembly lines, performing tasks from welding to intricate assembly with precision. Quality assurance is bolstered through AI systems that conduct detailed inspections, ensuring each vehicle meets strict quality standards. Predictive maintenance algorithms keep production equipment running smoothly, and AI-driven supply chain management ensures materials are delivered just in time, reducing lead times and costs. Additionally, AI facilitates customization at scale, allowing manufacturers to efficiently produce vehicles tailored to individual preferences.

-

In what ways can AI-driven robots assist in manufacturing?

AI-driven robots, or cobots (collaborative robots), work alongside humans to perform tasks ranging from assembly to inspection, significantly boosting productivity and efficiency. These robots are equipped with sensors and AI algorithms that enable them to learn and adapt to new tasks quickly. For example, in electronics manufacturing, cobots can be used for precise component placement and soldering, tasks that require high accuracy and consistency, thereby reducing errors and increasing throughput.

Want to Achieve Your Goals? Book Your Call Now!

We Fix, Transform, and Skyrocket Your Software.

Tell us where your system needs help — we’ll show you how to move forward with clarity and speed. From architecture to launch — we’re your engineering partner.

Book your free consultation. We’ll help you move faster, and smarter.

Let's Discuss Your Project!

Share the details of your project – like scope or business challenges. Our team will carefully study them and then we’ll figure out the next move together.

Thank You for Contacting Us!

We appreciate you reaching out. Your message has been received, and a member of our team will get back to you within 24 hours.

In the meantime, feel free to follow our social.

Thank You for Subscribing!

Welcome to the Devox Software community! We're excited to have you on board. You'll now receive the latest industry insights, company news, and exclusive updates straight to your inbox.