Integrate and manage all core aspects of your business in a single omnichannel solution, ensuring smooth operations across your enterprise. Devox can develop a system that centralizes production, supply chain, inventory, and order management data into one cohesive platform, enhancing decision-making and operational efficiency.

Why Devox Software

We build custom manufacturing software that tweaks and refines existing systems. We significantly enhance and accelerate your core operations — from intelligent production planning and quality traceability to multi-site supply ordering and ensuring materials reach the right place at the right time.

With engineering leadership and a Solution Architect in the lead, we help our customers figure out how they want to modernise their business: Do they want to integrate new components, carve out a new part of the operation, or replace a few key elements? Request a free manufacturing systems audit to identify the right way for your operations today, and gain a competitive advantage with our precise expertise and innovative AI Accelerator approach, which will save your resources by 30% to 50%.

Challenges We Overcome

- Modernize

- Build

- Innovate

Any risk to the line?

Production stays solid and on track across all our sites because we make sure to lock in the MES-ERP-SCADA connections upfront, and then we modernize in small bites.

Are ops flying blind?

We sort that out by putting clear ownership of data, and then we add in BI and AI, so everybody is looking at the same set of numbers.

Stuck in pilot mode?

We move from pilot to full-scale rollout by replicating validated processes across sites, guided by reference architectures, automated testing, and disciplined multi-site coordination.

Great tool, wrong system?

We design integration first: clear APIs, event flows, and data contracts that respect manufacturing systems and operations.

Built for one site?

We engineer our solutions to perform reliably across multi-plant, near-market, and regional manufacturing setups with well-governed configurations.

Five versions of truth?

We define a single, consistent production data model. That way, BI, analytics, and AI are all working with the same, trustworthy, production-grade metrics.

AI ready, data not?

Models learn from validated production signals because we stabilize the data layer first, aligning events, batch, and serial traceability.

Works in test, scary in ops?

We deploy through shadow mode, exception handling, and decision-support patterns, validating side-by-side with live workflows.

Does the model drift?

We implement feedback loops between operators, systems, and models, allowing AI to adapt to routing changes.

Manufacturing Software Development Services We Provide

Just like industry software development has many angles, so do the types of software engaged. Based on your requirements, Devox is ready to build different technical solutions from scratch exclusively for your enterprise.

-

Enterprise Resource Planning (ERP) Systems

-

Manufacturing Execution Systems (MES)

Gain real-time visibility into your manufacturing floor. We can design MES that tracks the entire production process, from raw materials to finished goods, ensuring that operations are efficient and compliant with industry standards. Monitor production metrics, improve workflow management, and maintain high-quality standards, all while reducing waste and minimizing downtime.

-

Supply Chain Management (SCM) Software

Optimize every stage of your supply chain, reducing operational cost and quickening delivery. We can build a custom SCM that enhances procurement, production, distribution, and logistics processes, allowing you to respond swiftly to market changes and customer demands.

-

Product Lifecycle Management (PLM) Software

We design PLM systems to manage the entire lifecycle of your products — from initial concept and engineering design to manufacturing and end-of-life. Our PLM solutions ensure seamless collaboration across teams, reduce time-to-market, and enhance product quality. By integrating design and manufacturing processes, we help you maintain competitive advantage through innovation and efficiency.

-

Inventory Management Systems

Inventory management software provides complete control over your stock levels, orders, sales, and deliveries. We will develop a custom system to help you reduce excess inventory, prevent stockouts, and optimize order fulfillment. With real-time inventory tracking, you can make informed decisions, improve customer satisfaction, and minimize operational costs.

-

Quality Management Systems (QMS)

QMS software ensures your products consistently meet industry standards and regulations. Our engineers will build systems that monitor quality at every production stage, from raw materials to finished goods. Facilitate continuous improvement, comply with regulatory requirements easier, and reduce the risk of costly product recalls or defects.

-

Production Planning and Scheduling

Get all the necessary tools to optimize your production schedules and resource allocation. You’ll be able to plan and manage production workflows efficiently, ensuring that resources are utilized effectively and deadlines are met. Reduce the risk of human error and adapt quickly to changes in demand or production capacity.

-

Industrial IoT (IIoT) Solutions

Enhance operational efficiency and drive innovation on the factory floor: IIoT platforms can connect your machinery and equipment, enabling real-time monitoring and predictive maintenance. We’ll develop a solution that gathers and analyzes data from sensors and devices, providing insights that help you optimize production processes, reduce downtime, and extend the lifespan of your equipment.

-

Warehouse Management Systems (WMS)

Let us build the WMS solutions to optimize your warehouse operations. We’ll provide real-time inventory tracking, streamline picking and packing processes, and improve shipping accuracy. Reduce errors, speed up order fulfillment, and improve overall warehouse efficiency without additional effort but by design.

-

Maintenance Management Software

Automate and manage your maintenance activities, ensuring equipment operates reliably and efficiently: our industrial software engineers can design solutions that track maintenance schedules, monitor equipment performance, and alert you to potential issues before they become critical. Minimize downtime, reduce repair costs, and extend the lifespan of your machinery.

-

Human-Machine Interface (HMI) Software

Our HMI solutions provide intuitive interfaces for operators to interact with machines and control manufacturing processes. We design user-friendly HMI software that simplifies machine operation, enhances safety, and improves productivity. With clear, responsive interfaces, your operators can manage complex processes with ease and confidence.

-

Environmental Health and Safety (EHS) Systems

Ensure your manufacturing operations are safe, compliant, and environmentally responsible. We can tune up the solution to manage and track all aspects of health, safety, and environmental compliance, from incident reporting and risk assessments to audits and regulatory submissions. You’ll facilitate real-time monitoring of safety metrics, getting a chance to take proactive measures and maintain a culture of safety and sustainability in your warehouse or manufacturing facility.

-

Production and Workflow Monitoring and Automation Apps

Identify bottlenecks, optimize resource allocation, and ensure that production runs smoothly without interruptions: Devox creates apps that monitor and automate your production processes and workflows, ensuring that your operations are as efficient and productive as possible. Our solutions provide real-time visibility into production activities, track KPIs, and automate routine tasks.

Benefits of Our Manufacturing Software Development

At Devox, we are positive that manufacturing industry software is the most beneficial when explicitly produced for a certain enterprise. Why so? Let’s get into it.

-

Your Enterprise’s Needs Exclusively

Address the unique challenges and requirements of your manufacturing processes, being positive any feature or mechanic you require is there to serve you. Unlike off-the-shelf solutions, custom software is built to fit your exact specifications, ensuring that every feature and function align perfectly with your business goals.

-

Complete Technical Excellence

The manufacturing industries' software is a grand and comprehensive solution featuring data management, security, quality control, and compliance. Make sure each such component is delivered impeccably: within tailored development, the Devox engineers will help you optimize production metrics, protect sensitive data, and enforce stringent quality standards.

-

Seamless Adaptability, Easy Integration

Custom manufacturing software offers seamless adaptability by integrating effortlessly with your existing systems and scaling alongside your business growth. This ensures smooth data flow, eliminates silos, and keeps your operations agile and responsive to industry changes, all while maintaining efficiency and minimizing errors.

-

Make Invested Costs Work for You

While the initial investment in custom software may be higher than purchasing off-the-shelf solutions, the long-term benefits often outweigh the costs. Custom software reduces inefficiencies, minimizes downtime, and enhances productivity, leading to significant cost savings over time.

-

Competitive Advantage

Enhance your unique strengths with the power of customization Devox can grant in terms of tailored development. A unique software for manufacturing company will not just bring out your advantages but give you a power your competition won’t yet possess, responding to market demands more effectively.

Our Manufacturing Software Development Process

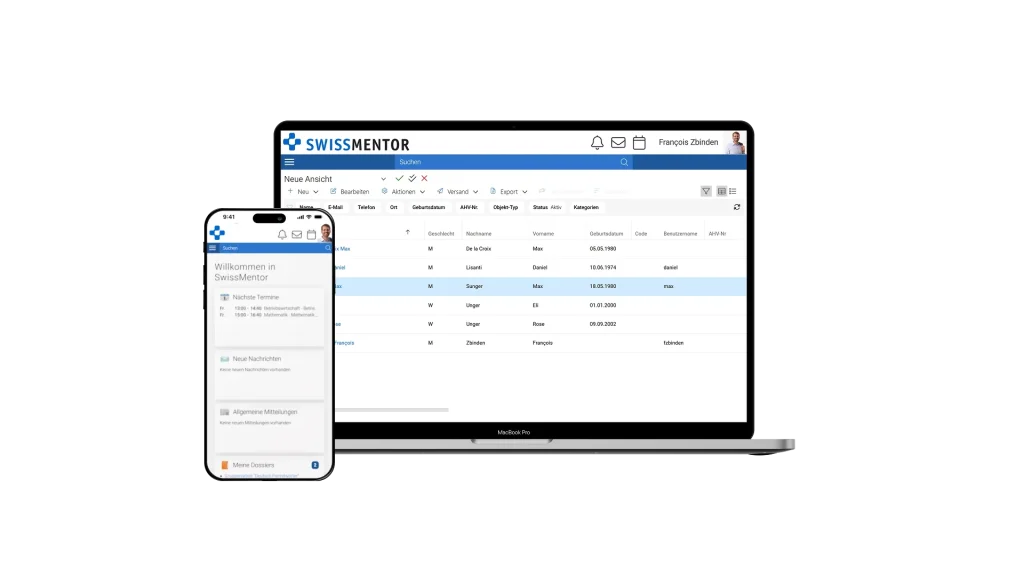

Modular LMS for Multi-Domain Learning: SwissMentor’s Enterprise-Grade Online Platform

A full-featured learning management system built to digitize education workflows, manage courses, and support online learning at scale.

Additional Info

- .NET Core

- PostgreSQL

- Angular

- Docker

- Kubernetes

- Azure

- SCORM

Switzerland

SAP-Integrated Automation for a Multi-State U.S. Enterprise

End-to-end tax compliance module embedded into SAP S/4HANA for a U.S. retail and distribution enterprise, automating multi-state filings, real-time calculations, and audit-ready reporting.

Additional Info

- SAP S/4HANA

- ABAP

- Avalara AvaTax

- Node.js

- PostgreSQL

- SAP BTP

- AWS

- Fiori

- CI/CD

- SOC 2

USA

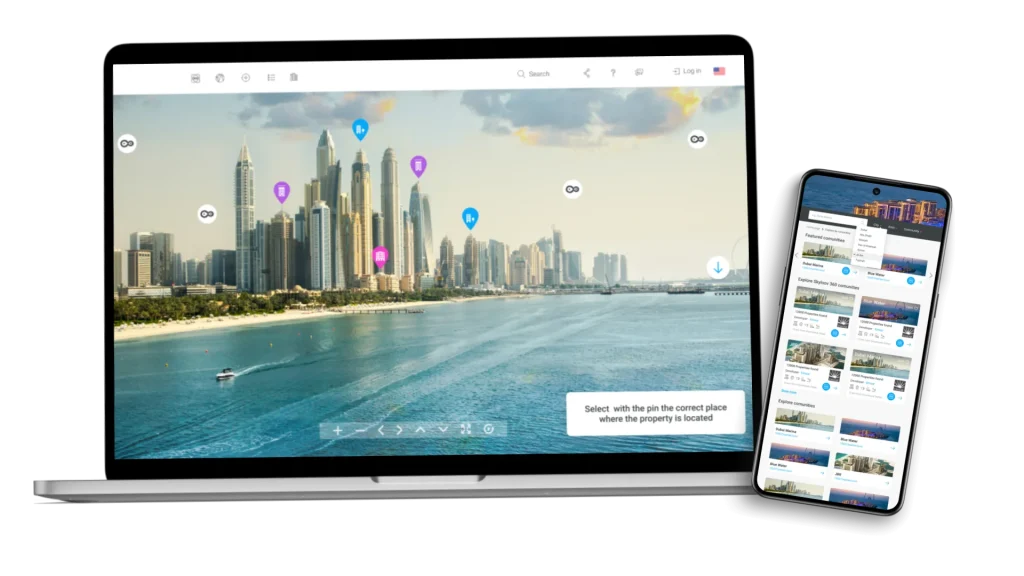

Immersive Property Portal with 360° View for Real Estate Buyers and Brokers

A real estate portal designed to streamline property search, simplify renting and buying decisions with personalized housing recommendations.

Additional Info

- NET Core

- MS SQL

- ELK

- Angular

- React Native

- NgRx

- RxJS

- Docker

- GitLab CI/CD

UAE

Testimonials

FAQ

-

What types of manufacturing businesses can benefit from custom software development?

Custom software development is beneficial for a wide range of manufacturing businesses, including those in automotive, electronics, pharmaceuticals, food and beverage, textiles, and heavy machinery. Whether you operate a small manufacturing unit or a large industrial enterprise, custom software can be tailored to streamline operations, improve productivity, and address specific challenges unique to your industry.

-

How long does it typically take to develop custom manufacturing software?

Industrial software engineering can take different time depending on the project’s complexity and scope. On average, it can take anywhere from a few months (sufficient for MVP) to over a year (a broad, full-scale product). During this time, we move on with the classic SDLC process (described in detail above), collaborating with your team and opting for the most viable solution for your case.

-

Can the software be integrated with my existing systems and equipment?

Yes, one of the key advantages of custom manufacturing software is its ability to integrate seamlessly with your existing systems and equipment. Whether you need to connect with ERP systems, MES platforms, IoT devices, or legacy machinery, we ensure that the software is compatible and enhances your overall operational efficiency. Our team specializes in creating solutions that work harmoniously within your current infrastructure.

-

What kind of support and maintenance do you offer after the software is deployed?

After deployment, we provide comprehensive support and maintenance services to ensure the software continues to perform optimally. This includes regular updates, bug fixes, performance monitoring, and enhancements as needed. Our team is available to assist with any issues that arise and to make adjustments as your business requirements evolve. We are committed to ensuring the long-term success of your software solution.

-

How do you ensure the security of the manufacturing software?

When developing a manufacturing software solution, we set security as one of three top priorities on a level with customization and user-friendliness. We implement robust security measures, including data encryption, secure coding practices, and access controls, to protect your sensitive information. Additionally, our software undergoes thorough testing to identify and mitigate vulnerabilities. We also provide ongoing security updates to safeguard your software against emerging threats.

-

How do you make changes without breaking production?

We never start with broad rollouts or risky platform overhauls. We begin by stabilizing the integration backbone and defining the first operationally safe slice, which systems, which flows, and what “no-downtime” means in measurable terms.

We minimize downtime risk by treating integrations as products — with clear, testable contracts in place, with clear, testable agreements in place. To start, we make sure the core “backbone” is solid, using things like versioned APIs and event schemas. We even run contract tests in CI to catch any potential problems.

But that’s not all, we also make sure there’s a safety net in place to catch any mistakes: idempotent handlers, event streams that can just be replayed, dead-letter paths, and good, clear visibility into what’s going on (how latency is running, error rates, how big the backlog is).

On the changeover side of things, we keep the impact of any change to a minimum, and we make the whole process feel almost anti-climactic. We make sure changes are deployed 1 line, 1 location, 1 capability at a time. We also run automated regression suites and maintain production-like environments to ensure predictable outcomes. Every deployment also comes with a runbook, a plan to roll it back, some “gates” for operational readiness, and a “shadow mode” for any new ideas to be road tested alongside the old way of doing things, so we can see if it works.

-

Which ERP, MES, and controls stacks have you worked with hands-on, and where did you own the integration end-to-end?

First, we look for a reliable operational foundation: time-series data that’s properly timestamped, consistently measured, and tagged with stable names that don’t change week to week. We also need a clear picture of your factory’s hierarchy, with sites, areas, lines, and machines all neatly mapped out and linked to your work centers. We also need identifiers that link everything across systems — order IDs, material IDs, and batch or serial numbers where applicable. On top of that stable base, we need a few key events that give us a glimpse of what’s really going on on the shop floor — state changes, orders starting and stopping, materials held back for not meeting specs, or scrapped and reworked — all of it. And a bit of context to help explain why things are varying in the first place: recipes, routing steps, tooling, shift changes, and environmental factors when they come into play. Once all that is in place, analytics become far more reliable, since every KPI traces back to the same events and consistent definitions.

As for AI, that comes down to how easy it is to get the data into a state where the models can actually learn from it. That means linking key outcomes (defect types, yield loss, downtime categories) to the exact conditions that caused them — at the right level of detail, whether that’s a machine cycle, operation, batch, or order. We also need to be able to check on the quality of the data, and make sure the models are staying on top of any changes that come up (like new recipes, new materials, or equipment going down). This gives you a path from trusted reporting that makes sense to automation that does too — explainable features, audit trails that work, and monitoring that tells you when the models need a refresh rather than when the process itself needs tweaking.

-

What data do you need on day one for analytics and AI to deliver real operational value?

We don’t need perfectly clean data to get started — that comes later. What we focus on first are key performance indicators that show what happened and why — such as spikes in scrap rates or production line downtime, along with the conditions that led to them.

For AI, the main enabler is label-ready historical data with lineage:

- outcomes such as defects,

- yield loss,

- unplanned downtime,

- late orders,

- or maintenance results, tied to when they occurred and linked to the conditions that preceded them at the right granularity.

If timestamps don’t align or event ownership isn’t clear, even the most polished analytics will fail to earn operators’ and engineers’ trust. They just won’t have any trust in it whatsoever. And right from the start, we also need to get some visibility into the stability of the process: are sensors drifting off or is some calibration or process change causing problems, and if so, what? We need to be able to spot all that so our models don’t get quietly degrading as the plant evolves. Once that foundation is in place, scaling becomes a natural progression — not a risky leap.

-

At the end of the engagement, what exactly do we walk away with? What’s tangible and usable by our team once you’re gone?

That includes a clear architectural vision, a blueprint for how components interact, and fully functional interfaces — APIs and others — each with version control, ownership, and governance rules to keep future changes in check. Every interface is backed up by automated tests to check its performance and integration, which run automatically as part of your build and deployment pipeline, as well as a reliable procedure for deploying updates and rolling them back if needed. This ensures deployments behave consistently across all environments.

One way or another, you get assurance that things are getting done right — in the form of measurable milestones and operational responsibility. Each slice comes with clear success criteria, traceability from business goals to performance indicators, and defined Service Level Objectives for availability, response time, and data freshness — all configured in the monitoring system from day one. Your team will be fully equipped to run, troubleshoot, and expand the platform as it grows into new areas.

Want to Achieve Your Goals? Book Your Call Now!

We Fix, Transform, and Skyrocket Your Software.

Tell us where your system needs help — we’ll show you how to move forward with clarity and speed. From architecture to launch — we’re your engineering partner.

Book your free consultation. We’ll help you move faster, and smarter.

Let's Discuss Your Project!

Share the details of your project – like scope or business challenges. Our team will carefully study them and then we’ll figure out the next move together.

Thank You for Contacting Us!

We appreciate you reaching out. Your message has been received, and a member of our team will get back to you within 24 hours.

In the meantime, feel free to follow our social.

Thank You for Subscribing!

Welcome to the Devox Software community! We're excited to have you on board. You'll now receive the latest industry insights, company news, and exclusive updates straight to your inbox.