Table of content

Most manufacturers are unprepared for digital transformation. Only 8% of them use self-optimizing processes, while 6% can do complete digital modeling. It’s understandable why this is the case, given that achieving a satisfactory level of smart factory transformation typically requires a consistent investment of 2 to 4 years. However, there is always a shortcut.

Devox Software specializes in modernizing legacy systems and adopting AI for SMEs and enterprises. Through years of practice, we’ve acquired a pool of techniques to accelerate and propel results. This article will help you prepare your business for the future and grow in the digital age.

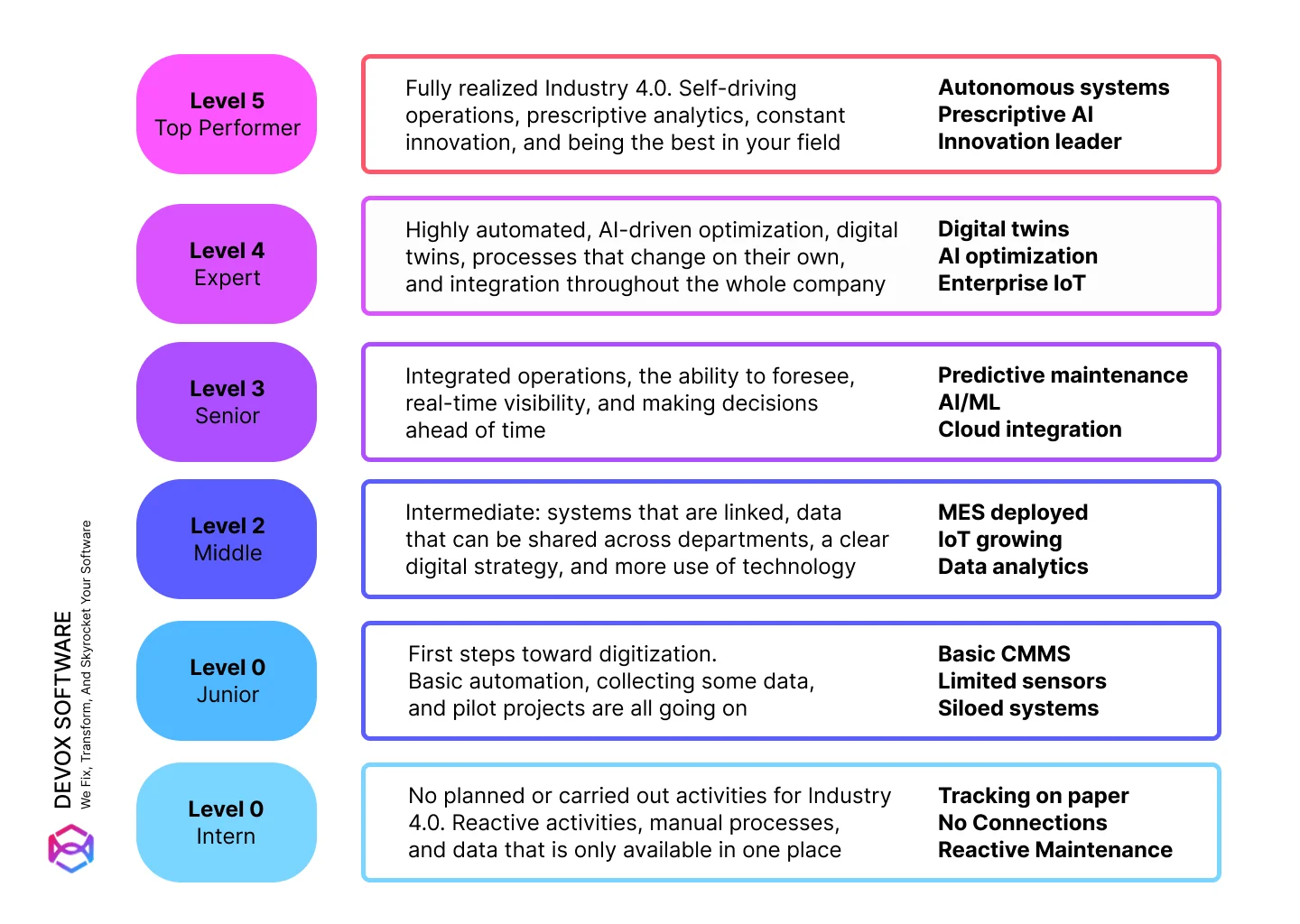

Preparedness Levels

Before we delve into the specific tips and tricks, let’s define the baseline expectations for digital transformations and the impact of smart factories on business. Despite common opinion, making a smart factory is a spectrum. It ranges from those who cover the basic needs to those who are top performers.

That’s why the most common assessment models introduce a six-level framework (0–5) to measure development in several areas. Your company’s position on this spectrum shows what it can do now and what it must do to advance.

What Is a Smart Factory? Key Systems It Includes

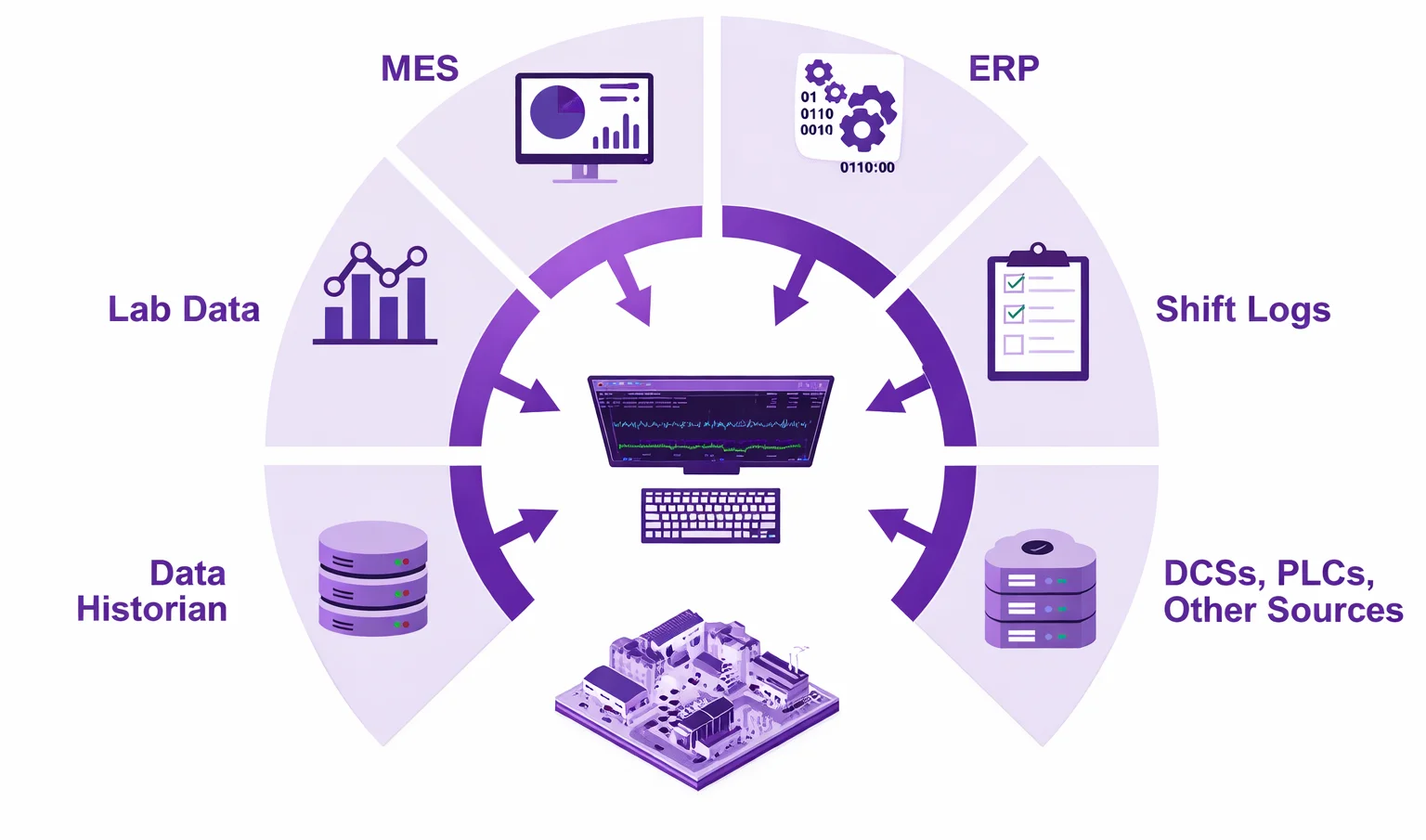

Smart factories need careful system design and strategic integration more than implementing cutting-edge technologies. Before adding AI or predictive analytics, it’s important to ensure that all of your systems, data, and people are connected and working together. Here are the most important things that every manufacturer needs to do right.

- Data Connectivity: A smart factory is impossible without a connected data ecosystem. Data silos, because of which data is processed in different systems, complicate effective decision-making and leave gaps in data flows.

DataPARC helps with data integration, enabling you to monitor things in real time, fix problems faster, and get more accurate reports. It also makes sure that operators, engineers, and leaders are all using the same information.

- Machine Learning and Advanced Analytics: Get information from data to find patterns, point out problems, and guess when things will go wrong so that teams may take action before they happen.

Moreover, as time goes on, machine learning algorithms improve with the processes become more optimal, unexpected downtime drops, and production output increases.

- Predictive Maintenance: Custom AI and ML solutions for manufacturing are designed to enhance the machinery performance and elongate its lifecycle. Based on the performance data and manufacturers’ recommendations, this system predicts when equipment will break down and schedules maintenance ahead of time in accordance with it. As a result, predictive maintenance reduces downtime.

- Automation: The next thing smart manufacturing heavily relies on is smart automation. It includes not only robotics but also making reports, updating inventories, and responding to alarms, including all repetitive and time-sensitive processes. By doing so, manufacturers reduce errors, enable consistent workflows, and empower workers with a more intelligent approach.

- Shop-Floor Control: MES takes what the ERP planned and schedules tasks, distributing work to stations and reporting progress back to planning. It monitors the progress of work, guarantees adherence to procedures through digital work instructions and step-by-step validations, and captures the real-time production event record.

As a result, that event stream becomes the only place to acquire information on traceability, compliance, OEE, and ongoing improvement.

- Quality Assurance: Quality Management Systems inspect outputs for deviations and nonconformances with recommendations for further rework and scrap. This allows you to detect and document what occurred and the reasons behind it, helping to prevent similar situations in the future while preparing for customer and regulatory audits.

You can get real-time alerts about faults or discrepancies. The custom manufacturing AI system ensures the quality of the products at different manufacturing stages.

- Supply Chain and Scheduling: Secure Copy Protocol (SCP)/Advanced Planning and Scheduling (APS) tools align demand with actual constraints, such as material supply, production capacity, workforce, tools, changeovers, and lead times. This keeps schedules realistic, helps identify shortages sooner, and lets production quickly replan as things change.

- Operational Visibility: Operational visibility and collaboration are the shared “control room” for people. Dashboards and role-based views show live performance and exceptions, shift logs/e-logbooks record decisions and handoffs, and Andon-style alerts send issues (quality, downtime, safety) to the right owners.

- Cybersecurity: Cybersecurity separates OT from IT and limits the blast radius. Asset inventory reveals the actual devices on the network, secure remote access controls manage vendors and support, IAM/MFA regulates user permissions, centralized logging enables incident investigations, and OT monitoring detects unusual behavior before it results in downtime or safety risks.

Connectivity, MES/MOM, QMS, planning, operational visibility, and cybersecurity are what make smart factories work instead of mere visualizations.

In the next part, we’ll go over this step by step, from figuring out how mature your system is and filling in any data gaps to connecting MES/QMS/ERP, setting up a solid event stream, and only then adding analytics and AI.

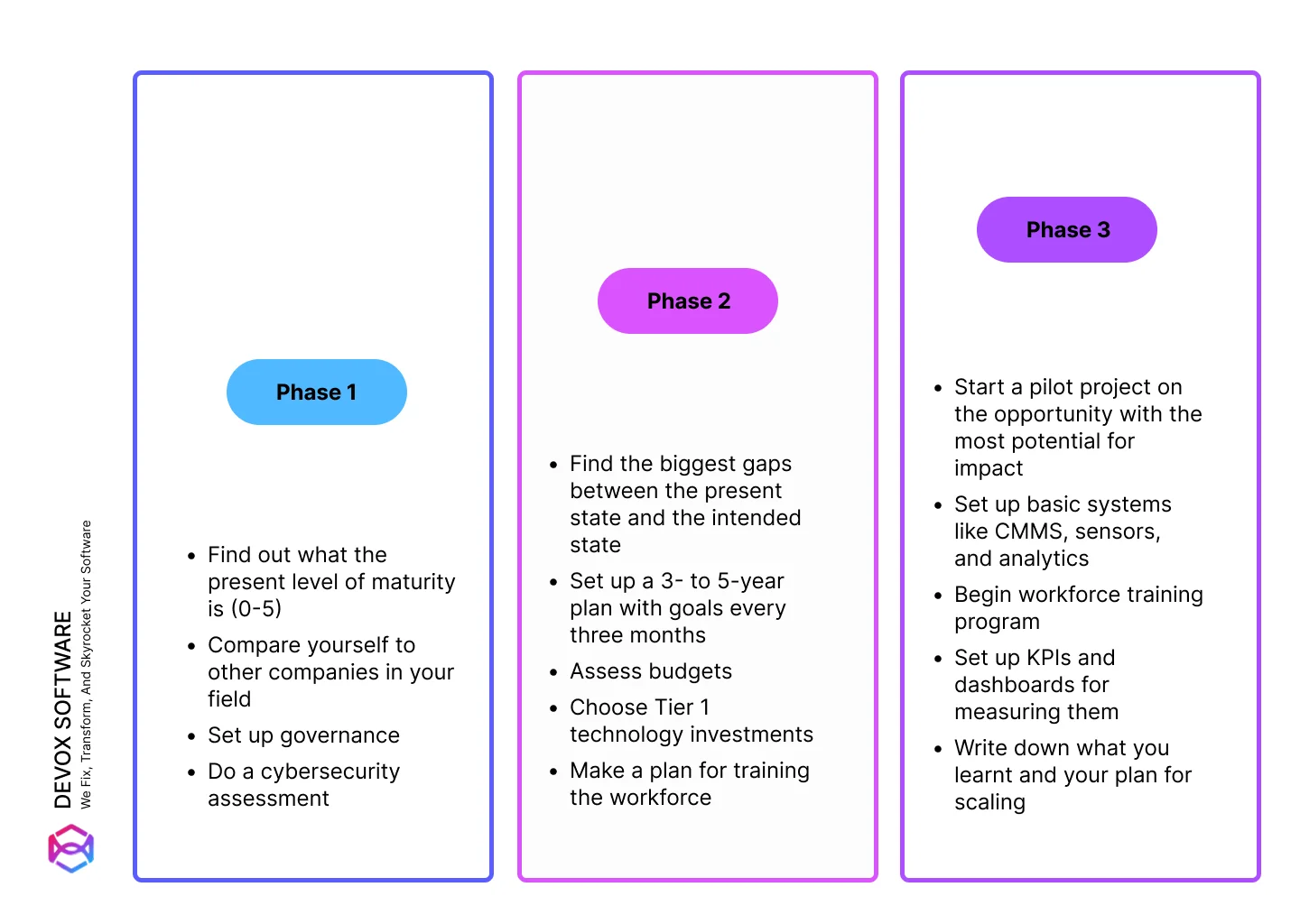

Planning Transformation Factories of the Future Roadmap: Step by Step

To reach digital maturity, each dimension requires certain skills. If one part is weak, the others won’t work as well. That’s why you need to act in all aspects: strategy and leadership, smart factory infrastructure, operations and processes, products and services, data and connectivity, and so on.

Furthermore, as previously mentioned, we cannot achieve rapid advancements overnight. You need phased work, stretched in time according to estimated roadmap. Additionally, although each project varies in complexity and specifics, the main reper points are the same.

You can then change the order of the steps based on your limitations, legacy footprint, and ROI priorities without violating the transformation logic. Devox Software can help you figure out how mature your business is, come up with a realistic rollout plan, and add the proper connectors and automation one step at a time, all without stopping production.

Phase 1: Foundational & Quick Wins

The goal of Phase 1 is to develop the minimum backbone for a smart factory that serves as a baseline level, containing everything else on it. Moreover, it shows a quick return on investment. What is included on this level of the pyramid:

- Data Analytics Platform: Establish a central platform for real-time visibility and insights, crucial for all other tech.

- IoT & Sensors: Deploy sensors to collect machine data and process data, providing the data skeleton.

- Cybersecurity: Implement strong defenses, including AI governance, as connectivity increases.

- Workforce Training: Start upskilling teams on user-friendly interfaces and new digital tools.

- Pilot Projects: You also need to add test solutions on a single line for quick ROI, moving gradually from simple to comprehensive.

In Phase 2, the smart factory stops being “connected.” After Phase 1, you get dependable data capture, real-time visibility, baseline cybersecurity, and validated pilots. The next step is to connect essential operational systems and turn insights into actions that happen every time.

Phase 2: Optimization & Integration

Phase 2 begins optimizing at scale once the necessary preparations are in place. This includes a set of measures from adding AI and machine learning to making the supply chain more visible so that production plans stay realistic even when things go wrong. In brief, Phase 2 links maintenance, production, quality, and planning so that advances don’t depend on repeatable, predictable routines.

- AI/ML Integration: Deploy predictive maintenance (65% adoption by 2026), AI for scheduling, and computer vision for quality control.

- CMMS/MES: Upgrade Maintenance Management & Execution Systems for better operational control.

- Cloud Infrastructure: Build scalable cloud capabilities to support growing data and applications.

- Supply Chain Visibility: Enhance tracking and build regional sourcing strategies for resilience.

At the end of this phase, you now have combined maintenance and execution systems, closed-loop actions, and AI/ML across all lines and plants. That’s the turning point: you’re no longer “experimenting with smart manufacturing”; you’re ready to put it into action.

The next phase is Phase 3, where you move optimization toward self-correcting operations. You can do this with digital twins, advanced planning, and continuous improvement loops that keep performance rising without having to constantly put out fires.

Phase 3: Advanced & Future-Proofing

Phase 3 is, in other words, the “future-proofing” stage. This is when your smart factory foundation and integrations are strong enough that you can safely work on advanced optimization without making a mess on the shop floor.

At this stage, all is prepared to further introduce AI-powered features: the data is accurate, the execution and maintenance are linked, and the quality workflows are easy to follow. With further complications, the goal shifts from simplifying and accelerating processes to introducing “self-aware” systems.

- Digital Twins: Implement for real-time simulation and optimization.

- Advanced Robotics: Integrate AI-powered cobots for complex assembly.

- Agentic AI: Scale autonomous scheduling for significant cost reduction.

- Circular Manufacturing: Adopt AI-driven biomimetic designs to cut emissions.

By the conclusion of Phase 3, the plant has not only become connected and optimized, but it has also become flexible. You can plan for change before you make it happen, safely automate complicated tasks, adjust your plans on the fly when things change, and make things more sustainable without losing performance. A production system will improve as technology, markets, and rules change.

A Cut To the Chase

In short, a smart factory roadmap isn’t a list of “Industry 4.0 tools” that you can buy. Adding AI to systems that aren’t connected will give results that don’t work well. You can make advanced optimization safe, quantifiable, and repeatable by first building the backbone and only then adding execution and maintenance.

That’s why the three-phase method works: Phase 1 shows ROI and standardizes data, Phase 2 translates insights into closed-loop actions across lines, and Phase 3 makes the plant future-proof with simulation, autonomy, and sustainability.

Devox Software can help you plan the goal architecture, safely combine old OT and IT systems, and deliver the roadmap in stages, from fast wins to full-scale optimization. Schedule a meeting to assess your present level, your ROI goals, and the quickest way to get your smart factory ready for production.

Frequently Asked Questions

-

Where should we begin if our factory is still in Industry 3.0?

To reach a smart factory badge, begin with the basics: link the important equipment signals, standardize tags and timestamps, create a single reliable real-time operational view, and protect the boundaries between OT and IT. Then run one pilot on a line that is having problems to show that it will pay off before you scale it. Our phase-related scheme shows the measures and timelines well.

-

Do we need to change our entire MES system to turn our factory into a smart factory?

Not necessary. Many plants begin with integrations and “overlay” features like event streams, dashboards, e-logbooks, quality capture, and maintenance procedures, all while keeping the old MES operational. The most effective approach relies on the level of risk involved, the rules in place, and the state of the existing execution layer.

-

When is it safe to use AI/ML for things like predictive maintenance, vision QC, and autonomous scheduling?

When your data is reliable and ready to be acted on as a smart factory, you have a steady connection, a consistent context, unambiguous ownership of decisions, and the ability to finish the loop through CMMS/MES/QMS workflows. Only then does the AI layer turn efficient.