Table of content

AI + IoT for Legacy Systems: Challenges and Best Practices

Most businesses put off modernization. “It’s not the time.” “It’s too costly.” “IoT and AI are just pretty dashboards.” The truth is that legacy systems silently steal from you. Statistics say that unplanned downtime costs taken solely reach $50 billion a year.

In reality, to modernize, you don’t always need to rip out your legacy system and replace it to make it “smart.” Devox Software has been working on modernization projects for almost a decade, so with this article, we want to unveil the exact tools and techniques for you to gradually update your IoT legacy systems. Let’s embark on this journey.

What Is a Legacy IoT System?

While a legacy application is just software that has been used for a long time, usually built on outdated architectures and languages, a legacy IoT system is much more. It’s an industrial or business “connected” setup that additionally uses older hardware. For instance, it has connectivity, but it’s not enough for modern practices like secure device identity, standard APIs, scalable cloud/edge processing, and regular updates.

In real life, it usually consists of a mix of older OT/IT parts: PLCs, sensors, SCADA, MES/ERP connectors, and so on. These parts have limited data visibility, fragile integrations, and security holes because they are no longer supported or are hard to patch. So if adding a new sensor or integration seems like “surgery,” then you have IoT legacy systems.

Let’s break them down before moving to updates, as modernization strategies largely depend on the current tech stack.

The IoT Components

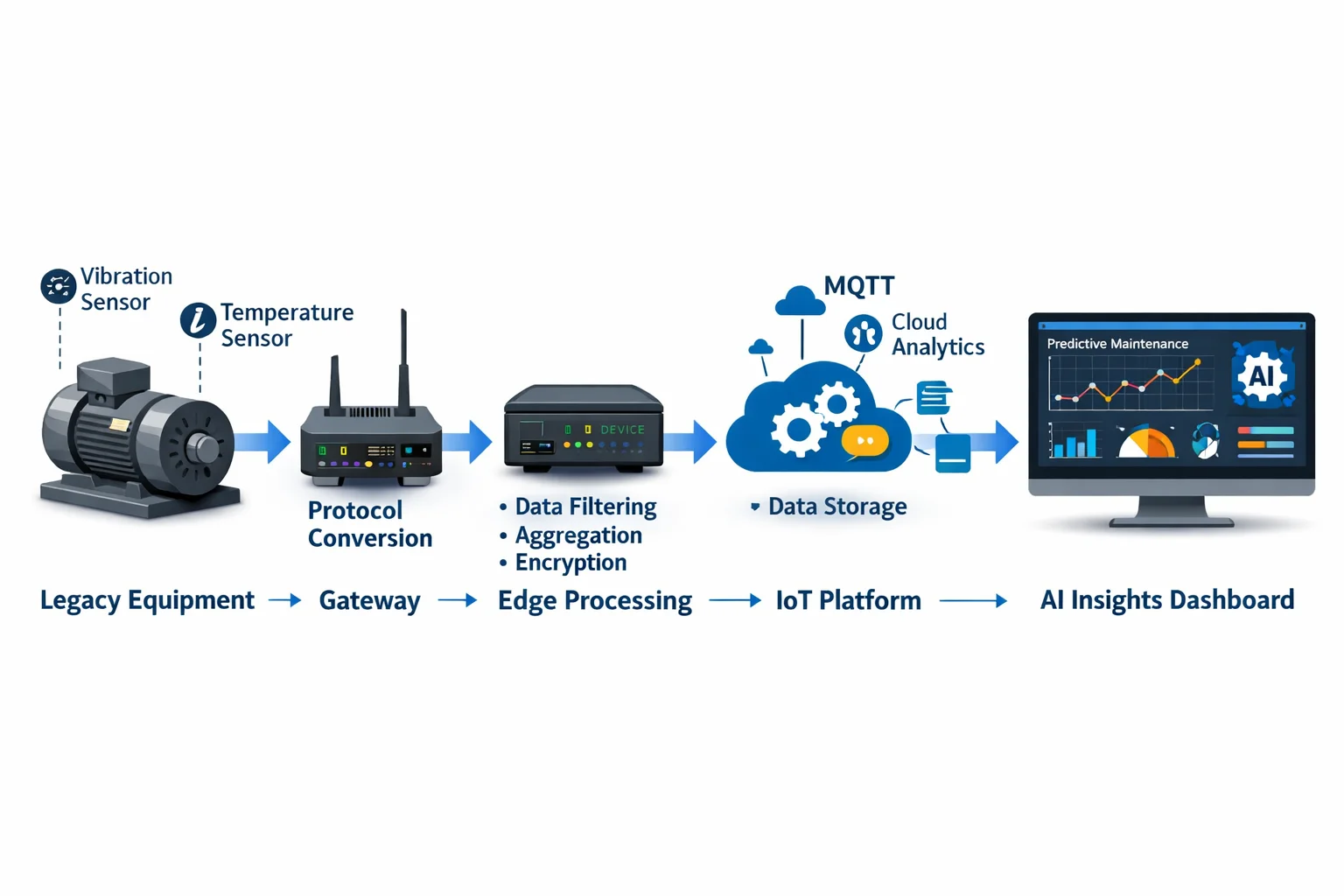

In a nutshell, the most repeatable patterns for IoT legacy systems look as follows:

- Sensors that work with IoT: Before modernization, ensure external sensors can record metrics like vibration, temperature, pressure, flow, current/voltage, sound waves, proximity, and more. This method allows you to receive current data before the machinery replacement takes place.

- Connections (ports, loggers, and gateways): If you have Ethernet or serial interfaces, you’ll be able to pull data directly. Usually, industrial gateways turn old protocols like Modbus and Profibus into transport protocols that your platform can use, such as MQTT and HTTPS.

- Edge processing: Edge devices filter, combine, change units/formats, and encrypt data before it leaves the plant network. This makes the cloud less busy and speeds up reaction time.

- AI with IoT: AI becomes useful when you have reliable signals. It can find anomalies, predict needed maintenance, predict quality, optimize energy use, and send “next best action” notifications.

If you step back, these components make up a straightforward logic chain: get the data from the machine, transport it safely, make it useful, and then make judgments based on it. In particular, sensors send you the signals, connection helps old protocols work with new platforms, edge processing keeps the flow quick and safe, and the IoT-and-AI layer turns raw telemetry into actions.

Now that this baseline is in place, modernization is no longer a risky “big bang” project. However, there are basic difficulties in the process.

How to Connect Legacy Systems to the IoT without Downtime: Step-by-Step Guide

The risk of downtime is one of the most challenging aspects of the modernization process. That’s why prioritizing this aspect is crucial when choosing a modernization strategy. This means you slowly IoT integrate legacy systems once preparations are made. Let’s consider the major stepping stones for modernization:

- Map Inventory: List your assets, ways they can fail, how they affect safety, and where downtime costs income the most.

- Plan the Signals: Choose the fewest signals that can explain the failure type.

- Choice of Connections: Use native ports; if it’s impossible, use loggers and add gateways to translate protocols.

- Edge Rules. Set up filtering, aggregation, and encryption so that you don’t send too much data to the cloud or disclose sensitive telemetry.

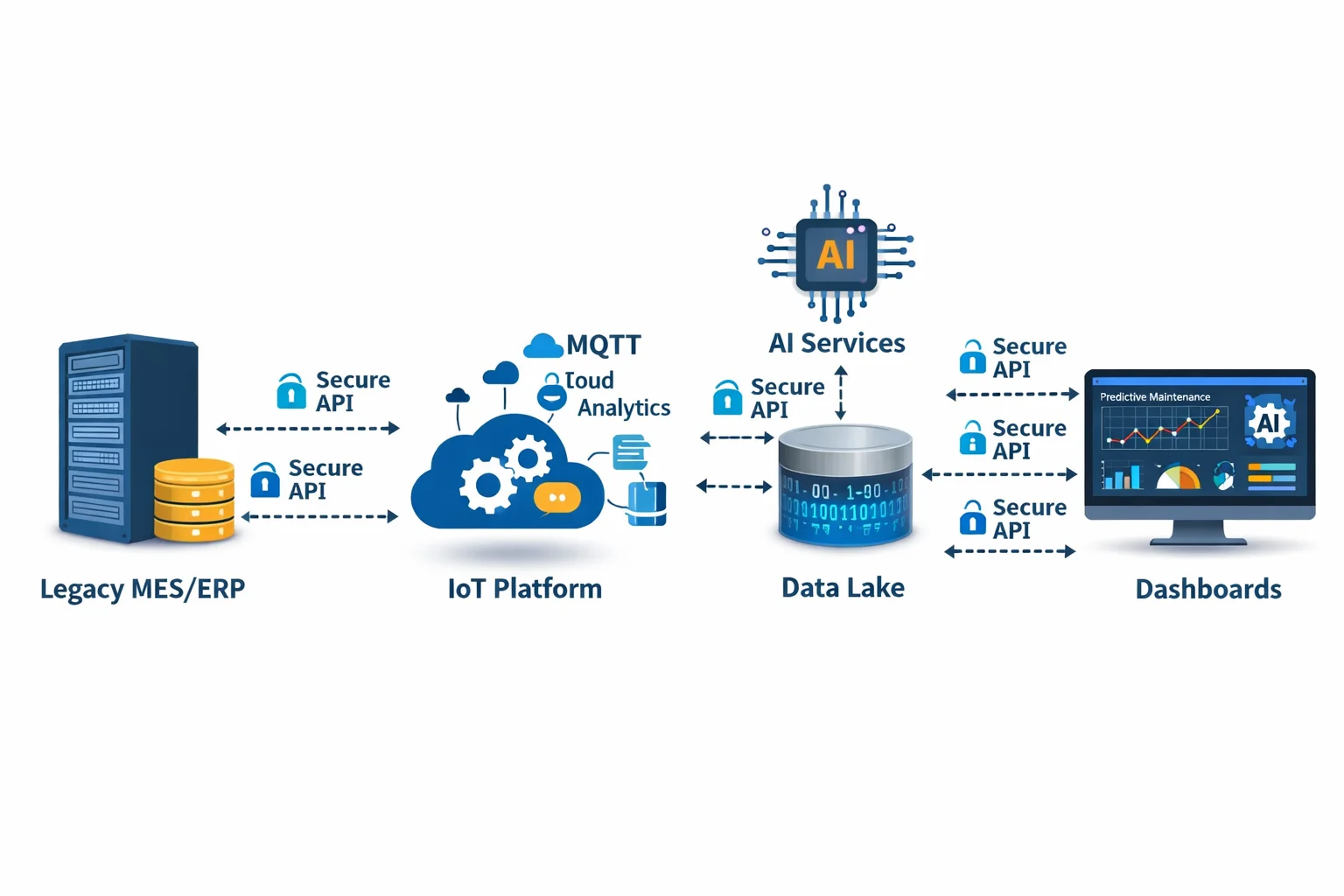

- Connect: It’s not about dashboards, but also alarms, work orders, and quality holds in existing CMMS, ERP, and MES workflows.

- Scaling: Show one measurable result, such as downtime, waste, or energy consumption. Then scale by the type of asset, not by the hype around the facility.

As a result, you need to keep in mind the parallel, “shadow” architecture: IoT should run adjacent to production systems, not inside them. This way, the business feels the impact before any major modifications start. Only take small stages, start with read-only, measure wins, and scale by asset class with rollback paths. This is the secret.

On Modernization Strategies Choice

Now, it’s time to consider the modernization strategies choice. This table compares refactoring, replacing, and rebuilding strategies as the main approaches for IoT legacy systems. If you’re interested in in-depth analysis of modernization strategies, this article about the full comparison of Refactor vs Rewrite vs Replatform approaches for your business offers a comprehensive overview and tips.

| When it wins | Hidden risk | Typical outcome | |

| Refactor | The equipment is valuable; downtime is expensive; and you need data fast | Security + interoperability debt if rushed | Fast telemetry + incremental modernization |

| Replace | Your tech asset is near end-of-life; compliance requires it | CapEx shock + long commissioning | Clean start, but slower ROI |

| Rebuild | The systems are blocking business change | Migration risk, data mapping complexity | Better agility if integration is solved |

As you can see, there are a few most-used strategies that can prepare your legacy IoT for modern standards and further implementation of AI. AI needs clean, consistent, and reliable inputs. It can’t make up for broken telemetry, missing context, incorrect timestamps, or weak integrations. So if your data flow is chaotic, AI will only learn noise and give you confident-looking but wrong recommendations. This is why you need to modernize first.

Best Practices for Implementing AI in IoT

The top experts of Devox Software have prepared a set of proven practices for you to accelerate and risk-free the IoT legacy systems modernization.

Integrating Sensors

Sensors help to get information about crucial machinery metrics, including vibration, temperature, pressure, flow, and more. IoT-enabled sensors accelerate daily tasks and enable advanced analytics like predictive maintenance, which helps to resolve problems before they get too far.

Additionally, IoT sensors help to meet higher environmental standards, attain their sustainability goals, and stay within the law. The most common sensor types for IoT legacy systems include the following:

- Vibration sensors: Identify problems that need fixing and look at the overall performance.

- Temperature sensors (resistance temperature detectors and infrared sensors): Detect overheating in electrical equipment and keep an eye on machine and facility temperature.

- Pressure sensors (strain gauges and capacity sensors): Detect the pressure in tanks and pipes to control flow rates and locate leaks.

- Flow sensors: One more sensor type, detecting leaks by spotting unusual flow patterns. Flow sensors also manage the flow rates in chemical reactors, which is crucial for safety.

- Current and voltage sensors: Like temperature sensors, current and voltage sensors monitor energy consumption so that businesses can lower their electricity bills.

- Acoustic emission sensors: Pick up sounds of gas or liquid escaping from pipes or storage tanks, which makes them an important safety measure.

- Proximity sensors: Inductive, photoelectric, ultrasonic, or capacitive sensors check that conventional safety measures are in place.

Installing is insufficient. You need to think about what kind of power source the sensor needs to work and whether it can communicate with the IoT ecosystem to integrate it deeply.

Using Connectivity Solutions

If you have an Ethernet or serial communication port, you can get data directly from it. Otherwise, data loggers store data that comes from sensors or equipment outputs. You then upload this information to the IoT legacy systems.

Moreover, industrial gateways change the data from the old equipment’s protocol, like Modbus, RTU/TCP, or Profibus, into a format that the IoT platform can recognize, like MQTT, HTTPS, or CoAP.

Edge devices or gateways can also help speed up the process of moving data to the cloud by processing it first. These gadgets might do this in several ways, such as

- Filtering: Eliminate noise or things that don’t matter from the data.

- Aggregation: Several pieces of data come together to make one value.

- Transformation: Edge computing changes the data into a format or unit of measurement that the IoT platform can understand.

- Encryption: Encrypting data makes it impossible to read, which makes it more secure and keeps anyone from getting into it without permission.

A Reality Check on Security

The most important practical measures for updating systems include:

- Role-based access and least privilege (operators, maintenance, engineers, and vendors should not have the same rights),

- Strong authentication for both users and devices (no shared passwords, no “generic gateway login”),

- Device identity so that every sensor/gateway can be checked before it sends or receives data.

Moreover, you also need to segment your network to keep operational technology and informational technology departments distinct and important control paths separate, while still letting monitored and regulated telemetry flow out. Secure key management and encrypted data transfer prevent the interception or modification of telemetry.

However, none of this works without proper operational hygiene, which includes frequent security checks, firmware updates when possible, configuration reviews, and constant monitoring for strange behavior.

Adding AI

While IoT gathers raw signals from old machines, AI then turns those signals into predictions, classifications, and suggested actions. This way, you don’t just keep an eye on your assets; you also manage them ahead of time. The best places for AI with IoT to add value are the following:

- Predictive Maintenance: Finds problems early, predicts breakdowns, and starts work orders before downtime.

- Predicting Quality: Connects process signals to defects and scrap risk while preventing problems in the middle of a batch.

- Energy Optimization: Identifies normal energy trends and marks waste, leaks, or loads that are too high.

- Process Optimization: Suggests modifications to setpoints based on patterns that people can’t see.

- Operational Intelligence: Delivers a short events summary, ranks alarms, and reduces alert fatigue.

Best practice from our experts includes starting with one high-impact use case and ensuring the edge-to-cloud data is clean and consistent. Only then can you expand AI-with-IoT models across asset classes.

Wrapping Up

If you still need to use old equipment and applications, modernization is the quickest way to get real value. The winning pattern is always the same: get the right signals, translate and protect them through gateways and edges, add the results to current operational systems, and then use IoT and AI for the business pain.

If you want to update old IoT systems, Devox Software can help with readiness evaluation for you to get top-notch expertise and a staged roadmap that you can follow without affecting production.

Frequently Asked Questions

-

Is it always cheaper to retrofit than to buy new equipment?

Yes, but only if you prepare for growth and don’t build up long-term debt for security and maintenance. The “base layer” of a computer is its system software. It runs the computer and lets additional programs work.

-

What is system software computer program testing AI IoT?

You can test the software with a computer program to show it works and doesn’t break when updated. Unit tests, integration tests, end-to-end tests, and performance and security tests are all common types of tests.

IoT and AI work together in real life: system software operates the edge devices/gateways and cloud services; IoT collects data from the real world; AI makes decisions based on that data; testing checks not just the code but also the quality of the data, the reliability of the sensors, and so on.

-

Before I can use AI with IoT, do I need to move everything to the cloud?

No. Edge and hybrid patterns are widespread. For example, you might preprocess data locally, transfer curated data to the platform, and then integrate the results back into old workflows.

-

What is the most common way that IoT programs on old equipment fail?

Instead of seeing it as a project to improve interoperability, security, and process, they see it as a device rollout.