Table of content

From Legacy WMS to Cloud-Based Platforms with Predictive Analytics

A legacy WMS, being ineffective and insufficient, adds up risks, not subtracts them. When Devox Software starts to modernize, we always see the same thing: when businesses switch from on-premises assumptions to a cloud-based inventory WMS, they opt to make forecasting, labor planning, and maintenance a part of the system.

Why? Predictive analytics initiates the process, while the cloud ensures its functionality across all warehouses and seasons. This story is the same.

When to Switch from a Legacy WMS to a Cloud-Based WMS?

Before we address the peculiarities of predictive analytics for WMS, let’s get a quick overview of the system tech background to ensure a seamless transition. What are the common traits of legacy WMS? Some common things with the old WMS are as follows:

- They don’t allow cloud deployment natively,

- They have few or no RESTful APIs for integration,

- They do not support mobile devices,

- Workflows that are hard-coded and don’t change,

- They are upgraded and patched by hand,

- They rely on vendor-specific knowledge or outdated programming languages.

Simply put, when your legacy WMS stops working, it’s time to move. However, in practice, the decision is not so straightforward. Let’s shape the most dangerous symptoms, pointing out that your business has outgrown your legacy WMS:

- Operational Volatility: Recurrent stockouts and overstocks despite “enough data,” increases in overtime during busy times, manual workarounds for replenishment and slotting, sluggish onboarding of new clients and sites, and integrations take months instead of weeks.

- Acute Need for Faster Cycles: Cloud WMS system gives you the foundation for real-time data flow, elastic capacity, and continuous updates that are core WMS cloud-based software advantages.

- High Operating Costs: When the cost of staying the same is more than the cost of change, you should shift to a cloud-based WMS (or cloud-based inventory WMS).

- Need for New Features: Predictive models need accurate, structured data to produce reliable results. Instead, in most legacy WMS systems, data is generally stored in batches, silos, and manual outputs, so the model can’t learn correctly.

Updating the WMS is what makes predictive analytics go from a dashboard with infographics to a self-learning system.

What Is Predictive Analytics?

To start with, predictive analytics is the feature that forecasts future events on the basis of the present operational data and statistics with the help of machine learning. This lets you stop problems before they happen, for instance, foreseeing stockouts, labor surges, equipment breakdowns, or delivery delays.

Let’s break down the most common features step by step.

Predictive Warehouse Operations Core Pillars

Modern WMS cloud computing simplifies scaling up and seeing what’s going on in real time, which is very helpful for businesses that have multiple warehouses and do a lot of online shopping.

1. Demand Forecasting

Demand forecasting predicts demand at the Stock Keeping Unit (SKU) level using past orders, seasonality, promotions, and outside signals. It manages replenishment, slotting, labor, and carrier plans, so operators don’t have to guess. As a result, AI can lower your inventory levels by about 20–30% by optimizing your inventory.

2. Inventory Optimization

Inventory optimization operates on speed, lead times, service targets, and limits metrics to determine what should be in stock and where it should be placed, rather than just focusing on what is already in stock. As a result, you face fewer stockouts, lower carrying costs, cleaner slotting, and better use of space.

3. Labor and Workforce Planning

Forecasting workload ensures that the right number of people with the right skills are working in the right shifts and zones. This enhanced allocation leads to fewer bottlenecks, reduced overtime fluctuation, and improved throughput predictability.

In particular, if teams compile timetables based on projected orders, execution time for each operation, and limitations, they will get a better capacity plan.

4. Equipment Maintenance and Asset Performance

Telemetry from equipment and operational signals helps avoid the risk of failure by 20-40% and then plan maintenance ahead of time by 20-40%. As a result, outages happen less often, assets live longer, and emergency repair costs are lower.

5. Route Optimization and Shipping Accuracy

Shipping accuracy is grounded in previous operations to identify carriers, guess when they will be late, and suggest routes and cutoffs, resulting in seamless operations, less freight waste, and more stable on-time delivery.

However, here is a word of caution. Predictive analytics won’t “fix” your warehouse if it’s still using WMS legacy resources like manual exports, spreadsheet planning, and batch replenishment procedures. The best effect relies on clean data, cloud execution, and decision loops that are linked to key performance indicators (KPIs).

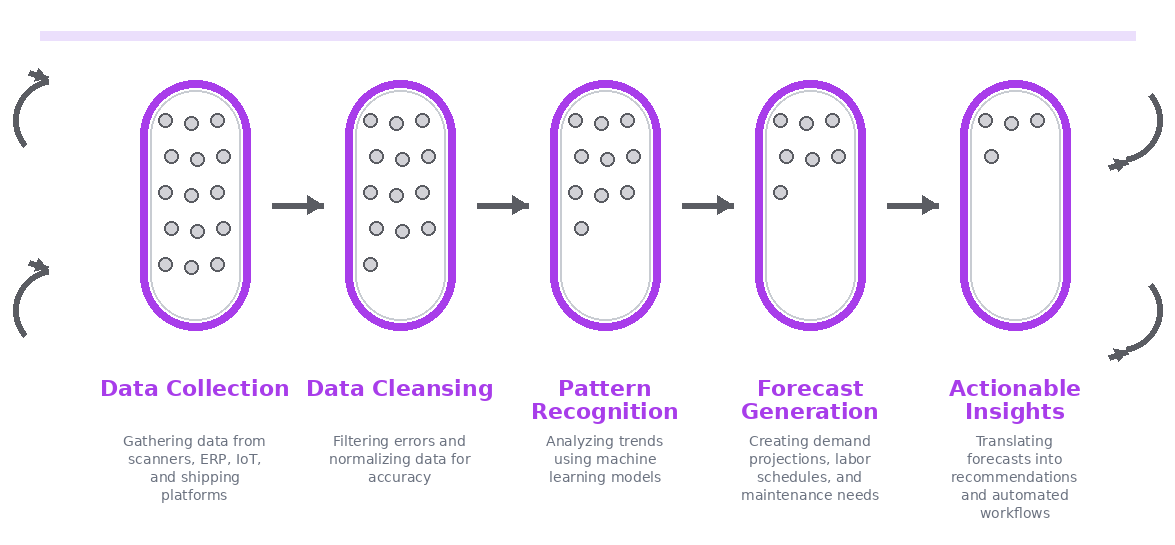

How Predictive Analytics Works Inside Modern WMS

Let’s go over how data moves around inside a modern WMS when predictive analytics is turned on:

- Data Collection: WMS gathers data from scanners, ERP systems, IoT devices, and shipping platforms for SKU, inventory levels, order trends, and equipment usage.

- Data Cleansing and Processing: The system filters out mistakes and cleanses the data.

- Pattern Recognition: Machine learning algorithms identify and analyze the patterns to deliver a product.

- Forecast Generation: Based on these patterns, the system provides forecasts: demand estimations, labor schedules, maintenance needs, etc.

- Actionable Insights: Finally, you turn disconnected forecasts into automated procedures.

You don’t just receive a static warehouse management system; you get a dynamic, breathing ecosystem that grows and changes with your organization.

Quantifying Predictive Analytics ROI

It’s simple to suggest that predictive analytics “makes things run more smoothly,” but let’s back that up with some data. Predictive tools can help you get measurable ROI in several common areas:

- Inventory Optimization: Better stock management can save carrying costs by 10% to 30%.

- Labor Efficiency: 15–25% improvement through data-driven scheduling.

- Less time spent with broken equipment: 20–40% fewer unexpected failures.

- Shipping Savings: By making the best decisions about carriers and routes, you can save 5–15% on shipping costs.

- Better Order Accuracy: Fulfillment is up to 99% accurate, which cuts down on expensive returns.

When you look at the numbers, predictive analytics may provide you a return on investment of 200% to 400% in the first year, depending on how big your business is and how many problems you have right now. Here’s a table comparing how both legacy WMS and cloud-based WMS with predictive analytics work.

| Legacy WMS behavior | Cloud-based inventory WMS + predictive behavior | KPI to watch | |

| Replenishment | Static rules, manual exceptions | Dynamic reorder points + alerts | Stockout rate, inventory turns |

| Labor planning | “Best guess” schedules | Forecasted workload by shift/zone | Overtime %, units/hour |

| Maintenance | Fix-after-fail | Predict-before-fail | Downtime hours, MTTR |

| Shipping | Cheapest carrier habit | Performance-based carrier selection | On-time %, freight cost/order |

| Change speed | Long release cycles | Faster iteration and rollout | Lead time for change |

As you can see, that’s not just a lift; it’s a change.

How to Implement Predictive Analytics: Simple Steps

- First, make your choices: what do you want to guess, and what will you do next? Change the order, the slot, the time, or the route.

- Check your old WMS limits: integrations, data quality, event timestamps, and gaps in master data.

- You don’t need a “big bang” to move to a cloud-ready architecture, but you do need a data pipeline that can grow (here is where cloud WMS system foundations come in).

- Start with one loop: demand forecasting or labor planning usually gives you quick wins.

- Put MLOps into action: keep an eye on drift, retrain on time, and let people know about problems.

- Change management: teach teams to “trust, but verify,” and get them to use it by showing them fast victories.

Notes to Sum Up

Predictive analytics is a set of decision loops for infrastructure and data flows that make operations less volatile. When you combine it with WMS cloud computing, you get real improvements. If you keep an old system, you’re paying twice: once for IT costs and once for the mayhem that comes with it. Moving from a legacy WMS to a cloud-based platform makes warehouse operations a measurable edge over the competition.

If you want to plan a modernization path that doesn’t need a risky “rip and replace,” ask Devox Software for a quick discovery to find the predictive loop with the highest return on investment. Let’s talk.

Frequently Asked Questions

-

Do we have to get a new WMS to employ predictive analytics?

Not necessarily; however, if the integrations and data latency are obsolete, it’s more cost-effective to rebuild the system instead of modernizing it.

-

What sets cloud WMS apart from SaaS WMS?

In practice, many vendors use these terms interchangeably. The most crucial thing, however, is whether you are getting real WMS cloud computing benefits, such as elastic scaling, faster updates, contemporary APIs, and the ability to quickly roll out changes across sites.

-

How to prevent downtime while we modernize our legacy WMS?

Most successful programs use staggered rollout and coexistence so that old and new parts can run at the same time while you move flows one at a time.

-

What data do we need for predictive analytics in our WMS?

Clean data is key to the right predictions. For this, you need orders, picks/receipts, inventory snapshots, lead times, task times, exceptions, and timestamps. Another layer is adding telemetry from IoT and equipment.

-

How can we ensure data accuracy during WMS migration?

It’s a distinctive procedure with its workflows and KPIs. Set rules for reconciling data, sample it, run it in parallel, and do “golden” inventory checks before the cutover. Ensure there is unambiguous ownership of master data, etc.

-

How long does a typical migration from a legacy WMS to a cloud-based WMS take?

Most migration cycles last from several months up to a year in the case of complex transitions. It fully depends on the scope. We offer rolling out in phases; however, to get an estimation, let’s talk.

-

Is cloud-based WMS safe enough for enterprises?

Cloud can be incredibly safe, but you have to work to make it safe. You still need secure SDLC, IAM, monitoring, and third-party component controls (with explicit shared-responsibility boundaries). To ensure the utmost safety and compliance, start by mapping the frameworks you must meet, then confirm what the cloud provider covers vs. what you must build. This is the shortest path.