Table of content

Imagine flying a airliner jet using only yesterday’s weather forecast. That’s what running logistics on legacy transportation systems feels like today — navigating volatility with outdated instruments, blind to the turbulence ahead.

McKinsey’s data show that while 85% or more of logistics companies see value from digital investments, fragmented systems and poor data quality remain key barriers to achieving real ROI. Up to 19% of logistics costs are attributed to inefficient handoffs between systems and vendors.

Welcome to a new generation of operational intelligence — logistics route optimization software that stream data as it happens, adapt to shifting signals, and refine every decision in motion. What has changed is not just the technology, but the speed at which decisions must be made. Rescheduling delivery routes in real time, dynamically adjusting freight prices, and automatically reconciling supply chain interruptions are now all part of the standard repertoire. Your old system, designed for linear workflows and batch updates, is simply not suited to this kind of responsiveness.

In this guide, we’ll show CTOs how to build for real-time responsiveness — from streaming architecture to decision logic that adapts on the fly. Every nuance matters, and we break them down: how to expose legacy logic, reduce integration debt, and design operations that move with the market.

What’s at Stake: Risks of Outdated Systems

In logistics, latency compounds. Legacy systems, structured for batch logic, introduce blind spots where real-time visibility should operate. As AI-native competitors use logistics network optimization software to optimize routes mid-transit and reprioritize inventory in-flight, enterprises locked into static platforms fall behind.

According to Gartner, over 75% of logistics disruptions stem from a lack of supply chain visibility. In the U.S. alone, inefficient handovers and poor telemetry may generate up to $95 billion in losses annually. Between 13-19% of logistics costs can be traced to ‘blind handoffs’, when parties can’t coordinate delivery or operations effectively due to siloed systems.

Fragmented legacy ecosystems, built without native data pipelines or sensor integration, cannot provide granular, real-time snapshots. When IoT devices, TMS modules, and 3PL partners operate on isolated stacks, signals like temperature breaches in cold chains, ETA shifts at ports arrive too late or never at all. The impact goes even further: a lack of real-time visibility prevents proactive intervention. If temperature deviations in a cold chain are detected hours too late or never detected at all, the damage affects not just operations but also reputation. In regulated industries, these blind spots not only lead to fines but also to a permanent loss of certification and customer trust.

Integration Debt: Every New Tool Becomes a New Problem

Most logistics tech stacks now use 10+ different digital tools. Yet, over 40% of executives say these solutions take longer than expected to deliver ROI due to data fragmentation and lack of system integration.

Conversely, legacy cores, designed without modularity, resist change. Every new integration requires custom wrappers, point-to-point hacks, and constant monitoring. Over time, this builds “integration debt”: a fragile mesh of adapters, batch scripts, and unscalable middleware.

To emphasize, digital twins increasingly sit atop SCM stacks as an optimization layer. On the negative side, older platforms are often based on outdated security mechanisms — unencrypted protocols, monolithic authorizations, and unpatched modules. When cloud-native and API-first technologies are used, the attack surface increases. Without adaptable, policy-driven security models, sensitive operational data is exposed: GPS routes, freight contracts, even freight manifests.

In practice, though, outdated infrastructures lack the telemetry and resilience to respond quickly or recover fully. Resilience now depends on continuous observability, distributed detection, and adaptive defenses embedded throughout the logistics fabric.

The Cost Curve of Inertia

Operational overhead in legacy-bound environments trends upward. Manual workarounds, escalations, and exception handling — all increase as systems struggle to absorb variability.

For legacy-reliant players, what begins as a technical limitation quickly manifests as a margin problem. And in a low-margin industry like logistics, those basis points define the difference between growth and stagnation.

When and What to Modernize

If you’re ready to tackle, target the areas where latency becomes cost: price quotes delayed by hours, shipping logic blind to live weather, outdated inventory signals unfit for real-time decisions.

Begin with business-critical processes under pressure: dynamic pricing, demand-driven routing, and SLA-sensitive fulfillment. If these workflows still rely on manual overrides or batch synchronization, they’re blocking growth.

#1. Watch for Signal Loss in the Tech Stack

To clarify, legacy platforms often sit in the center of logistics operations, but they weren’t built to emit signals. Can your warehouse system broadcast real-time slotting updates? Can your TMS expose ETA shifts via webhook, not CSV?

If your data architecture absorbs events only after they settle into a database, you’re building decisions in a stale state. Modern logistics runs on event-driven architecture. Look for silent systems, those that don’t publish, subscribe, or stream. That’s where modernization delivers exponential visibility.

#2. Every manual workflow points to a process ripe for automation.

In other words, wherever there’s copy-paste between apps, there’s a business case for intelligent automation. Invoice reconciliation. Load confirmation. Exception handling in returns.

Automate through adaptive intelligence, not brittle logic:

- Let AI agents capture patterns, refine decisions, and evolve with operational nuance.

- Use ML to score and route claims by probability and cost impact.

- Apply NLP to filter, cluster, and escalate inbound messages without human drag.

Every workflow compressed through autonomy returns hours to core execution and creates surface area for scale.

#3. Prioritize Capabilities

Rather than modernizing application by application, focus on core capabilities.

Avoid the trap of system-by-system replatforming. Instead, modernize around capabilities. Want predictive ETAs? Build a real-time event ingestion layer first. Want proactive risk mitigation? Start with a digital twin of your supply chain. Then let that capability tap into existing systems via API or middleware.

This approach drives modular investment and avoids the classic trap: replacing one monolith with another.

#4. When Systems Lock You into Yesterday’s Logic

Still, sometimes the signal is structural: systems that force business users to work around them. If planners use spreadsheets to override your TMS recommendations, or if your WMS requires IT tickets for rule changes, you may find your current systems are no longer enabling agility — they’re limiting it.

Modern logistics platforms empower the edge: planners, dispatchers, even AI agents. When your current stack can’t support continuous iteration, it’s time to shift.

Tech Stack for the Future-Proof Logistics

Modern logistics platforms must detect change, evaluate impact, and execute decisions in real time. Every layer of the stack such as compute, data, intelligence, and integration serves this goal.

Legacy systems evolve efficiently through modular architecture, unified data, embedded intelligence, seamless integration, operational visibility, and team alignment.

Composable Architecture

Decomposing legacy functions into modular services reduces complexity. Pricing, dispatch, and tracking engines operate independently, enabling faster iteration and lower risk. Legacy cores remain stable while adjacent services modernize.

A cloud-native, event-driven architecture provides the elasticity and regional awareness required to meet shifting demand. Stateless services and container orchestration maintain uptime while adapting to throughput changes across routing engines, pricing modules, and planning systems.

Unified Data Fabric

Operational signals—inventory, transit status, carrier performance—must converge into a unified data plane. Streaming ETL and real-time validation feed models and dashboards with accurate, current state.

Streaming data feeds every decision layer. Telemetry from trucks, inventory sensors, and partner systems flows into real-time pipelines. These signals fuel predictive models and automated actions, enabling systems to respond faster than any manual process.

Embedded AI/ML

Intelligence must sit inside core workflows. ML models prioritize loads, recommend routes, and trigger alerts. LLMs generate documents and summaries. Automation at the decision point removes friction and scales execution.

AI generates business value when embedded in decision execution. A predictive ETA model must feed dispatch sequencing. Load planning models must adjust to dynamic constraints. AI systems that drive operational logic reduce delay, cost, and human intervention.

Interoperability enables scale. Legacy systems wrapped with modern APIs can broadcast order status, available capacity, and pricing logic to the ecosystem. These APIs form the connective tissue of orchestration and unlock composable workflows.

API-Powered Integration

Every critical function—rate quotes, shipment updates, compliance checks—exposes clean, versioned APIs. These interfaces transform static systems into callable services and accelerate ecosystem collaboration.

Process Visibility & Digital Twins

Digital twins reflect operational reality. Combined with process mining, they reveal inefficiencies and allow simulations. Teams move from reaction to preemption using real-time visibility.

Organizational Enablement

Platform teams and domain squads own services and ship changes. CI/CD pipelines, observability tooling, and low-code controls give teams control without chaos. Transformation scales when teams scale delivery.

Security operates at runtime. Tokenized access, identity-aware controls, and anomaly detection protect data and logic across distributed actors. In high-trust, multi-party logistics networks, security must match the operational speed.

This is how legacy becomes logistic optimization software platforms — reliable at the core, dynamic at the edge.

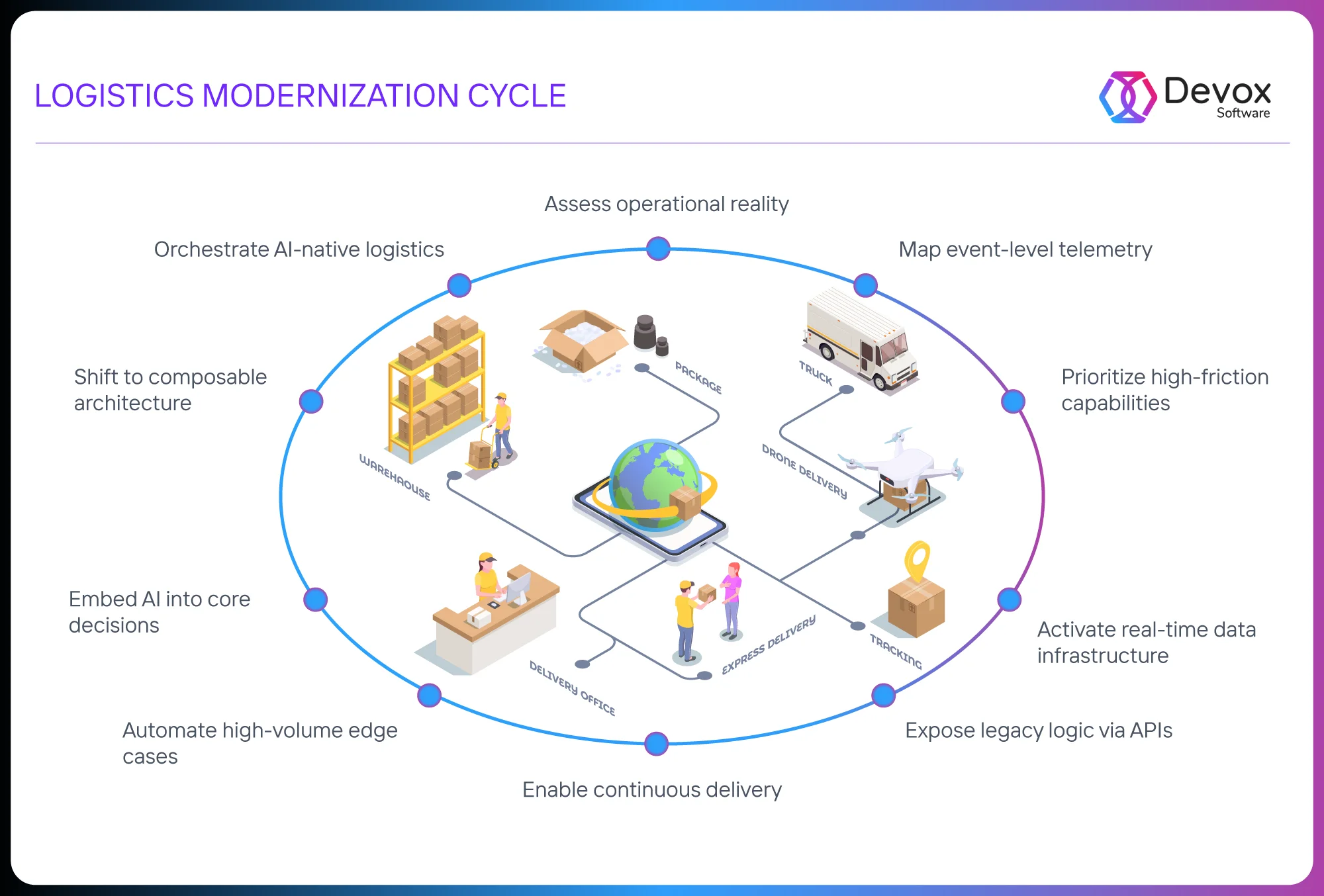

Roadmap: From Assessment to Impact

To illustrate the concept, strategic modernization in logistics begins with operational truth. Before you change the architecture or the tools, you must first gain clarity. You need to understand how the processes work, how exceptions cascade, and where the value gets stuck. This is where process mining comes into play. It maps how operations really run and reveals bottlenecks, loops, and hidden workarounds in legacy systems.

Prioritize capabilities that generate immediate operational leverage. That may start with predictive ETA modeling, intelligent slotting in fulfillment centers, or autonomous dispatch planning. The objective is immediate business lift, not technical idealism.

Below is a proven progression of 12 interlinked modernization cycles that logistics leaders follow to achieve measurable operational lift:

- Assess Operational Reality. Understand real-world workflows, exceptions, and latent bottlenecks before designing change.

- Map Event-Level Telemetry. Capture granular signals across planning, fulfillment, and transportation to create a unified operational truth.

- Prioritize High-Friction Capabilities. Identify the workflows where latency creates cost, and target them for automation or augmentation.

- Activate Real-Time Data Infrastructure. Build streaming pipelines and shared models that support live-state decision-making, not stale reports.

- Expose Legacy Logic via APIs. Wrap core functions in callable interfaces to enable orchestration across internal and partner systems.

- Introduce Intelligent Automation Agents. Deploy ML agents to auto-classify, route, or escalate high-frequency operational decisions.

- Automate High-Volume Edge Cases. Embed low-code and AI-driven automation in repetitive processes like exception handling or reconciliation.

- Embed AI into Core Decisions. Use ML and LLMs in slotting, ETA prediction, contract summarization, and anomaly detection.

- Shift to Composable Architecture. Refactor monolithic systems into modular services that scale and evolve independently.

- Enable Continuous Delivery. Empower platform teams to iterate quickly with CI/CD, trunk-based development, and domain ownership.

- Orchestrate AI-Native Logistics. Let real-time engines coordinate dispatch, pricing, and fulfillment across dynamic networks.

- Monetize Operational Intelligence. Turn visibility and precision into revenue — SLA-based services, predictive SLAs, and customer guarantees.

By focusing on adaptability rather than replacement and alignment rather than ambition, leading logistics organizations are moving from static systems to intelligent ecosystems. At every step, change is magnified — from visibility to prediction, from reaction to orchestration, from friction to flow.

A global mid-sized logistics company was under increasing pressure. Legacy TMS and WMS systems were struggling to keep pace with customer expectations, while margin erosion from missed SLAs and manual exception handling was limiting reinvestment. What started as a technical refresh quickly evolved into a strategic modernization program led by the CTO and Head of Operations.

An AI-powered logistics optimization software, fed with real-time capacity, constraints, and estimated arrival times, replaced the static planner and reduced empty miles by 17% in just 60 days. At the same time, the low-code bots saved more than 600 hours of manual document work per month. The savings? They were invested in customer-oriented self-service tools, not in more staff.

Instead of ripping out the legacy core, they exposed the business logic via APIs and wrapped it in a composable orchestration layer. This allowed them to integrate new services such as provider portals, forecasting models, pricing systems without having to rewrite the base. Within a year, they were no longer just “moving freight” but optimizing freight networks.

The logistics department, once a cost center, began to generate new revenue: SLA-supported services, premium fulfillment, and real-time delivery guarantees for first-class customers. An initial push for modernization evolved into a platform business that moves goods with predictive control and monetized precision.

Automation Intelligence: A New Operational Lever

The edge now negotiates. Autonomous systems reshape supplier terms using current capacity, spend patterns, and market dynamics. No scripts. Intelligence at the edge goes deeper than visibility — it now makes decisions.

This shift moves contract logic closer to where value is created — at the frontline. Instead of waiting on legal or procurement cycles, dispatch planners see auto-generated supplier options ranked by cost, reliability, and sustainability balance. The negotiation surface becomes dynamic.

The most compelling evidence comes from real-world deployments like DHL’s AI-powered coaching platform. Generative AI is now intervening deeply in operations: cameras in the cab, trailer sensors, tablets for on-site maintenance. Samsara’s work with DHL proves this. By streaming computer vision alerts and real-time driver telemetry into an AI-powered coaching system, DHL Express reduced road accidents by 26% in the first year and cut total accident costs nearly in half. These safety gains translated into lower claims, improved retention, and stronger P&L resilience.

The same edge-AI layer identifies idle assets across the network. Sensors expose utilization gaps, with 10-20% of fleets standing idle for weeks. Redeploying or liquidating this latent capacity releases millions in trapped capital.

AI also detects negotiation latency. Pactum’s large-scale automation models prove that frontline negotiation agents — embedded at the edge — recover working capital, strengthen supply resilience, and shift control back into operations.

McKinsey’s 2025 State-of-AI survey confirms the shift: 78% of enterprises already deploy AI in operations. Among logistics leaders, generative use cases are expected to triple by 2027. For those who’ve moved procurement to the edge, the returns arrive before the quarter closes.

“Every contract becomes a living asset when AI shapes terms in response to real-time context.”

— Harvard Business Review, “How AI Is Reshaping Supplier Negotiations”, 2025

For CTOs, the message is clear. Edge AI paired with live data streams doesn’t just optimize movement — it orchestrates commitments. Safety, utilization, supplier terms — all update without escalation. The result: fewer delays, higher margins, and logistics teams that no longer chase contracts — they shape them.

Checklist: Are You Ready to Modernize?

Another key point: evaluate each dimension against your current state.

Evaluate each dimension against your current state. A company with three or more gap indicators enters a “modernization mandate” zone where competitive risk accelerates.

| Dimension | Readiness questions CTOs should ask | Clear readiness signal | Gap indicator | First action to close the gap |

| Process visibility | Do we see every order-level event and exception in real time? | End-to-end telemetry feeds dashboards and process-mining maps; latency measured in seconds | Blind spots appear in the map; manual status checks persist | Deploy event capture on TMS / WMS and run process-mining discovery |

| Data readiness | Can analytics engines consume unified, high-quality data without rework? | Streaming pipelines deliver clean, schema-governed data to ML feature stores | Multiple CSV hand-offs; data quality fixes happen in Excel | Launch data-profiling sprint; implement real-time validation rules |

| Integration surface | Does every core capability expose a secure API? | External partners call status, pricing, and capacity endpoints through documented interfaces | Point-to-point scripts or EDI only; integration backlogs block customer requests | Wrap legacy logic with REST/GraphQL gateway; publish an internal API catalog |

| AI/automation foundation | Are machine-learning models or bots already driving high-volume decisions? | AI predicts ETAs, assigns dock slots, validates invoices; accuracy tracked in prod | Rule engines dominate; planners override decisions frequently | Stand up pilot model on high-variance lane; embed feedback loop for retraining |

| Security posture | Do zero-trust policies and continuous audit protect every data flow? | Fine-grained RBAC, token-based access, and automated compliance evidence | Legacy VPN tunnels, shared credentials, and limited incident telemetry | Introduce identity federation and real-time log aggregation; run a security drill |

| Change capacity | Can cross-functional squads release platform updates weekly? | CI/CD pipelines, feature flags, and domain-owned microservices support rapid iteration | Quarterly release cycles, centralized change boards slow delivery | Form a platform team, adopt trunk-based development, and deploy feature toggles |

Conclusion

In conclusion, legacy platforms powered global trade for decades — now modernization is turning that legacy into a launch pad. The logistics leaders of 2025 run architectures that listen, learn, and self-optimize. Data flows in streams, AI acts in milliseconds, and security adapts in real time. Every version that cuts decision latency boosts margins and deepens trust.

Achieving this goal requires clear telemetry data, modular services, and a culture that embraces rapid change. Companies that use process mining, simulation-based decision intelligence, and agile product leadership achieve sustained profitability even in the face of economic turbulence. Continuous development creates resilience, strengthens teams, and maintains brand relevance.

Legacy systems hold strategic value — make that knowledge visible, useful, and scalable.. Expose it, enrich it, extend it. When systems talk to each other in real time and AI supports every micro-decision, logistics transforms from a cost center to a growth engine. The path is open, and time is ticking. Accelerate.